We Make Your Testing Easy with Eddy Current Instruments

An Eddy Current Tester is a type of Non-Destructive Testing (NDT) instrument that is used to inspect metal components for surface and near-surface faults such as cracks, corrosion, and other defects. It works by inducing an alternating magnetic field in the metal, which creates circulating electric currents, known as eddy currents, in the metal.

The eddy currents in turn generate their own magnetic fields that can be detected by sensors in the tester. The changes in the magnetic field can then be analyzed to determine the presence and location of faults in the metal. Eddy current testing is a fast and efficient method for detecting faults in metal components and is commonly used in industries such as aerospace, power generation, and petrochemical. Visit us to our store!

An Industry Leader in manufacturing and supplying Various categories of Microscopes and Hardness testing Equipment Now involve in developing Eddy Current Testing machines

Eddy current testers detect flaws in conductive materials by utilizing the principle of electromagnetic induction. These inspection tools are highly portable, making them ideal for examining complex shapes in challenging locations. Common applications include tubing and surface inspections.

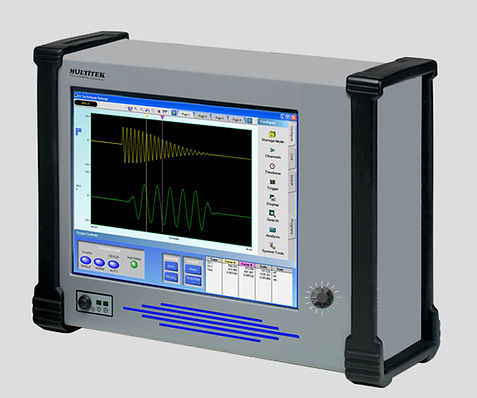

Multitek Technologies, is an industry leader in the design, manufacture, and sale of Hardness testing machines and Microscopes also involved in developing Eddy Current Instruments.

The Multitek team of innovative engineers, designers, and sales consultants will SOLVE YOUR CHALLENGES with logical solutions. Our skilled machinists, fabricators, electronic technicians, and assemblers build products to meet your unique needs. Our technical service experts are dedicated to working with you, anywhere and anytime. They travel in all over India to ensure your equipment is running right and your staff is trained to operate it. Our exceptional product life and manufacturing expertise make us an industry-leading as manufacturer and supplier.

EDDY CURRENT TESTING METHOD

Widely used in automotive, aerospace, nuclear and metal industries, Eddy Current inspection is one of many electromagnetic methods used in Non-destructive Testing (NDT). It uses electromagnetic induction to detect and characterize surface and subsurface flaws in conductive materials.

Eddy Current testing equipment can be used for applications such as cracks detection (discontinuities), measurement of the metal and coating thicknesses, detection of corrosion and erosion, or the electrical conductivity and magnetic permeability measurements. Eddy Current inspection is an excellent method for detecting surface and near surface flaws.

Some examples of applications:

-

Inspection of welded tube, bar, wire

-

Heat treatment, hardness, coating verification and measurement

-

Sorting of steel grades and alloys

-

Conductivity measurement on plate

Eddy Current Instruments for Many Industries

Every industry has its unique needs and challenges when it comes to non-destructive testing. Below are the list of industries where eddy current instrumentation are powerful and used in such industry -

-

Aerospace

-

Automotive

-

Manufacturing

-

Military and Defense

-

Oil and Gas

-

Power Generation

-

Railway

-

Transportation

Our systems are using Eddy Current instruments for automatic in-line inspection of tubes, pipes, bars, wires, cables (in Automotive, Aerospace, Nuclear and Metal industry). Eddy Current rotating systems such as rotating heads are used for longitudinal defects detection, magnetizing units and encircling coils for short flaws detection, sectorial magnetizing units are dedicated to weld inspection, and coil’ supports for nonferrous materials.

Our goal is to develop and create performing solutions to improve safety, efficiency and profitability of our customers. We are constantly researching and improving the performances of our equipment and systems.

Eddy Current Testing Equipment FAQs

How does eddy current measurement work?

Eddy current testing is a nondestructive testing also known as NDT method that can be used for various inspection and detection applications. Eddy current inspections work using an electromagnetic field to measure the response from a material. It generates magnetic fields, which induce a current that flows in a test piece (e.g., a conductor such as a coil). This influences the magnetic field, as well as the magnitude and phase of voltage in the coil. Any changes in conductivity, such as defects or thickness differences, can affect the resulting eddy current. This technology can then be used to measure distance or to detect flaws in conducting materials such as corrosion, erosion, wear, pitting, baffle cuts, wall loss, and cracks.

About Us -

Multitek Technologies is a leading manufacturer and supplier of Non-destructive Testing equipment, specialized in Microscope and Hardness testing related equipment’s as well as developing Eddy Current and Ultrasonic inspections.

We handle the design, conception, and development of every component of our systems (mechanical, electrical, software). Our goal is to provide high quality turnkey solutions to improve the safety, efficiency and profitability of our partners and customers.

Our skilled and multidisciplinary engineering team is constantly researching, investing and developing new technologies to meet our customer’s expectations. Additionally, we can create customized machines such as hardness tester, microscopes and automatics cutting machines in our in-house lab. We have dedicated engineers and professional having rich experience in same.

Founded in 1989, Multitek Technologies is a private and independent company based in New Delhi, India.

We are proud to work with some of the most branded companies such as Tata Motor, Maruti Suzuki, Hero and Honda, very specific in automobile and in healthcare industries. We have an experience of more than 25 years to understand customers need and delivered things very efficiently and effectively. For more information Contact Us!

Our machines are supplied or used in all over India now we have customer in different -2 states of India.